What should be paid attention when choose fiber laser machine?

Fiber laser machine use fiber amplifier developed by fiber adulterated REE. Because any optical amplifier can form laser machine through appropriate feedback mechanisms, fiber lasers can therefore developed based on fiber amplifiers. Currently developed fiber laser machine use mainly REE as the gain medium. Since fiber laser’s fiber core is very small, in the role of the pump light the inner fiber can easily form a high power density, resulting in laser material laser level "inversion." Therefore, when adding the appropriate positive feedback loop (constitute a resonance cavity) can form a laser oscillation output. In addition, as the matrix fibers have a very broad fluorescence spectrum, therefore, generally can be made tunable.

What the difference between laser cutting machine and ordinary cutting machine?

Cutting machine is divided into flame cutting machine, plasma cutting machine, laser cutting machine, water cutting machine etc.,laser has four characteristics of high speed,high direction, high color and high coherence. After focusing laser beam has high energy density. Laser cutting, drilling and welding have been widely used in industry. In this years laser processing technology has been quickly developed, it increase every year at the rate of 15%~20%. The progress and development of laser processing technology will gradually expand plate processing application. Laser cutting machine will be suspendible sheet metal processing mean in 21 century. In the future development trends, laser cutting machine will replace traditional cutting machine, laser cutting machine will continuously improve, continuously develop,continuously innovate in the future.

how to properly choose metal laser cutting machine?

Metal laser cutting machine has unique advantages in cutting metal material. How could customer choose proper metal laser cutting machine?

1、Cutting precision. Cutting precision is a key factor to measure performance of metal laser cutting machine, laser cutting equipment with high cutting precision is customer’s first choice.

2、Cutting speed. Specification of metal laser cutting machine decide the cutting speed, customer hope process more products within certain time. So cutting speed is also a factor when customer purchase metal laser cutting machine.

3、Life of metal laser cutting machine. Cost of a metal laser cutting machine is very high, if it has short life, customer need to change machine frequently, which add produce cost. So use life is also a key factor when customer choose metal laser cutting machine.

How to choose laser marking machine?

First of all, people should know the material of products. Different materials have different laser absorption degree. Paper box PET with color use generally 10W laser machine.

Secondly, when know a particular brand of laser marking machine, people should know whether it use metal sealing laser tube. Currently laser tube with metal sealing has the best sealing function, it would not leak. Ceramic tube and glass tube has relative bad sealing function, easy to leak and easy to damage during transportation.

Thirdly when check the stability of equipment,man should know life of laser tube, man should also know that manufacturer use which technology to control opening and closing of laser tube. Because laser is like a lamp, more time to open and close, easier to damage, so it is better to choose laser machine whose laser tube has less opening and closing times. Many people think that laser tube with greater power has longer life, which is a generally mistake. They think greater power has more gas and slower consumption. Actually, laser tube with greater power produce more energy during working, if it can not promptly and effectively dissipate, laser tube will be burned. So equipment over 50W need generally water cooling, they have a huge cooling system.

Choosing suitable laser marking machine is the first step of getting satisfied marking. We suggest that user know basic purchasing knowledge of laser machine before buy it, then choose with your supplier the most suitable marking machine.

What are the requirements of choosing laser machine?

1、laser machine export goog beam quality, including model and model stability;

2、whether laser machine has enough output power, whether the energy is stable;

3、laser machine has good maintenance, has functions of fault diagnosis and linkage,downtime should be short;

4、laser machine has high reliability, it should work continuously under strict industry processing environment

5、Convenient operate, clear function of controlling keys, it can refuse illegal operation and prevent laser machine from damage

In addition, price is also a important factor to consider.

How to choose laser engraving machine?

1、engrave on which material:depending on different type of laser,it can be divided into YAG laser engraving machine and CO2 laser engraving machine, the former one apply mainly to metal products, latter one apply mainly to non-metal products.

2、Size of products: chose scale of laser engraving machine, it’s not generally good to chose big scale, for equipment with big scale is more expensive, but some bad quality equipment has unstable laser output average degree on big scale, which lead to different depth on the same surface of engraving product, so choosing the most suitable scale is correct.

3、Speed:only when use faster speed in short time to produce more products

4、can create higher profit, so the speed is the key to get order and earn money.4)Precision:the biggest difference between laser engraving and traditional engraving and manual engraving is precision, laser engraving has highest precision among the three engraving craft.

5、Power of laser tube: according to different engraving material and content

6、chose suitable laser tube wattage, for example: engraving acrylic and color plate need not much laser tube power, engraving wood and stone material and any other material need high-power laser tube.

7、After-service: after-service is very important for equipment, but people always has a wrong concept that machine can conveniently and quickly get components because machine is made in china.But people don’t know that the qualified imported equipment is not easy to be damaged, they need not often to be repaired. In return, equipment with bad quality will pay attention to maintenance, because of frequent damage.

A. Holographic hot stamping foil in customized design

Features:

Clear and bright holographic visual effect, vivid image to show your logo uniquely. ( Better than hologram sticker)

Can combine comprehensive security technology well including holographic technology and non-holographic technology. It can get a wonderful combination for efficient anti-counterfeiting & eye-catching packaging.

Technology: Dot-Matrix, 2D, 2D/3D, 3D True color, Dynamic effect, Combinated holography, Multi-channel viewing transfer, Partial Metallization/Demetallization etc.

Hidden feature for authentication:

* Micro-text (can be disclosed by magnifier glass, Holographic and non-holographic micro-text for multi-choice)

* Dynamic-Micro effect (Dynamic effect as overt feature, Micro-text as covert feature)

* OCRE (our particular proprietary technology, the details can be find in the below file.)

Can be applied on the packaging with high precision and finish the operation on the automatic stamping machine at high speed.

Match with various hot stamping machine including Bobst , Steuer, Yawa etc

The hologram can be attached on the pack firmly and can’t be moved.

Two type application: single logo pattern, repeat logo pattern (Your choice depends on the exact packaging need).

B. Hologram sticker

Features:

Vivid image to show your logo with nice holographic effect.

Can combine comprehensive security technology well including holographic

technology and non-holographic technology.

Wonderful combination for efficient anti-counterfeiting & eye-catching packaging

Technology: Dot-Matrix, 2D, 2D/3D, 3D, True color, Dynamic effect, Combinated holography, Multi-channel viewing transfer, Demetalized hologram, Numbering etc.

Hidden feature for authentication:

Micro-text (can be disclosed by magnifier glass, Holographic and non-holographic micro-text for multi-choice)

Dynamic-Micro effect (Dynamic effect as overt feature, Micro-text as covert feature)

OCRE (our particular proprietary technology, the details can be find in the below file.)

Can be made to have the tamper-proof/evident feature that when you try to move the hologram label to use on the fake packaging, the hologram will be self-destructive and can't be used again.

Can finish the operation on the automatic labeling machine at high speed.

(We can produce the stickers for you in sheets or tape/roll, the sheet one can be operated manually, the tape/roll one can be operated on the automatic labeling machine.)

How to choose optical transceiver?

1.Classification of Optical Transceivers

In Application:

Ethernet application rates: 100Base(100M), 1000Base(1000M)and 10GE

SDH application rates: 155M, 622M, 2.5G and 10G

In Package:

Package types: 1×9, SFF, SFP, GBIC, SFP+ , XENPAK, XFP and etc.

1×9 package——welding type optical transceiver, with rate not higher than 1000M, normally with SC connector

SFF package——welding type small-form optical transceiver, with rate not higher than 1000M, normally with LC connector

GBIC package——hot-pluggable 1000M optical transceiver, with SC connector

SFP+ package——hot-pluggable small-form packaged transceiver, with rate up to 10G, normally with LC connector

XENPAK package——applied in 10G Ethernet, with SC connector

XFP package——10G optical transceivers for 10G Ethernet application and SONET application, normally with LC connector

In LD types: LED、VCSEL、FP LD、DFB L

In wavelengths: 850nm、1310nm、1550nm and etc.

In usage methods: non hot-pluggable (1×9 and SFF) , hot-pluggable (GBIC, SFP, SFP+, XENPAK and XFP)

2.Basic technical parameters of Optical transceiver

Data rate, transmission distance, connector type, working environment, wavelength, temperature and fiber type

3.Usage life of optical transceiver

International standard- 7x24 hours constant working for 50,000 hours (equivalent to 5 years)

4.Fiber connector types

SFP transceivers are with LC connector, GBIC transceivers with SC connector; other connectors with FC and ST

5.Working temperature:

Commercial temperature: 0~+70℃;

Industrial temperature:-45~+80℃;

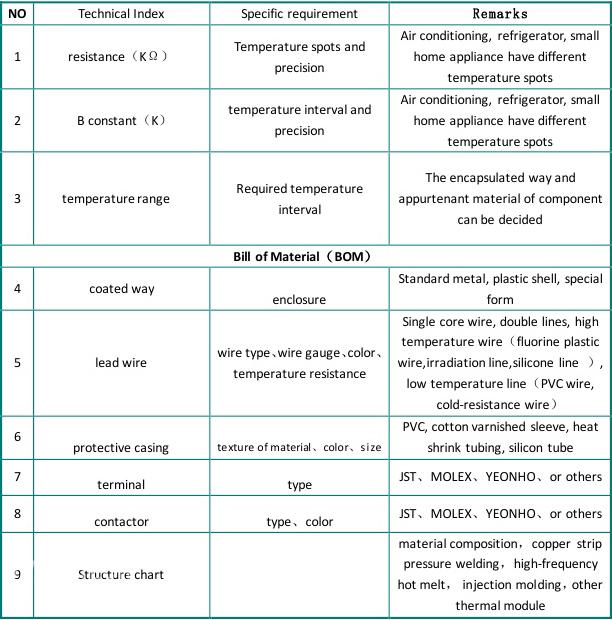

Selection Points of Temperature Sensor

A、 To determine the appropriate operation temperature range, in order to select suitable manufacturing materials of sensor and manufacturing technology;

B、 To determine the nominal resistance of thermistor (B constant) and the operation temperature according to the circuit design, in order to guarantee satisfactory accuracy of temperature measurement and control;

C、 To determine the accuracy of thermistor sensor in order to acquire the high cost performance according to the actual product needs;

D、 To determine the encapsulation mode, structure size, electrical connection mode, special protective measures of sensor of sensor according to the installation structure of sensor.

Products List of NTC Temperature Sensors: